🔹 GENERAL DESCRIPTION

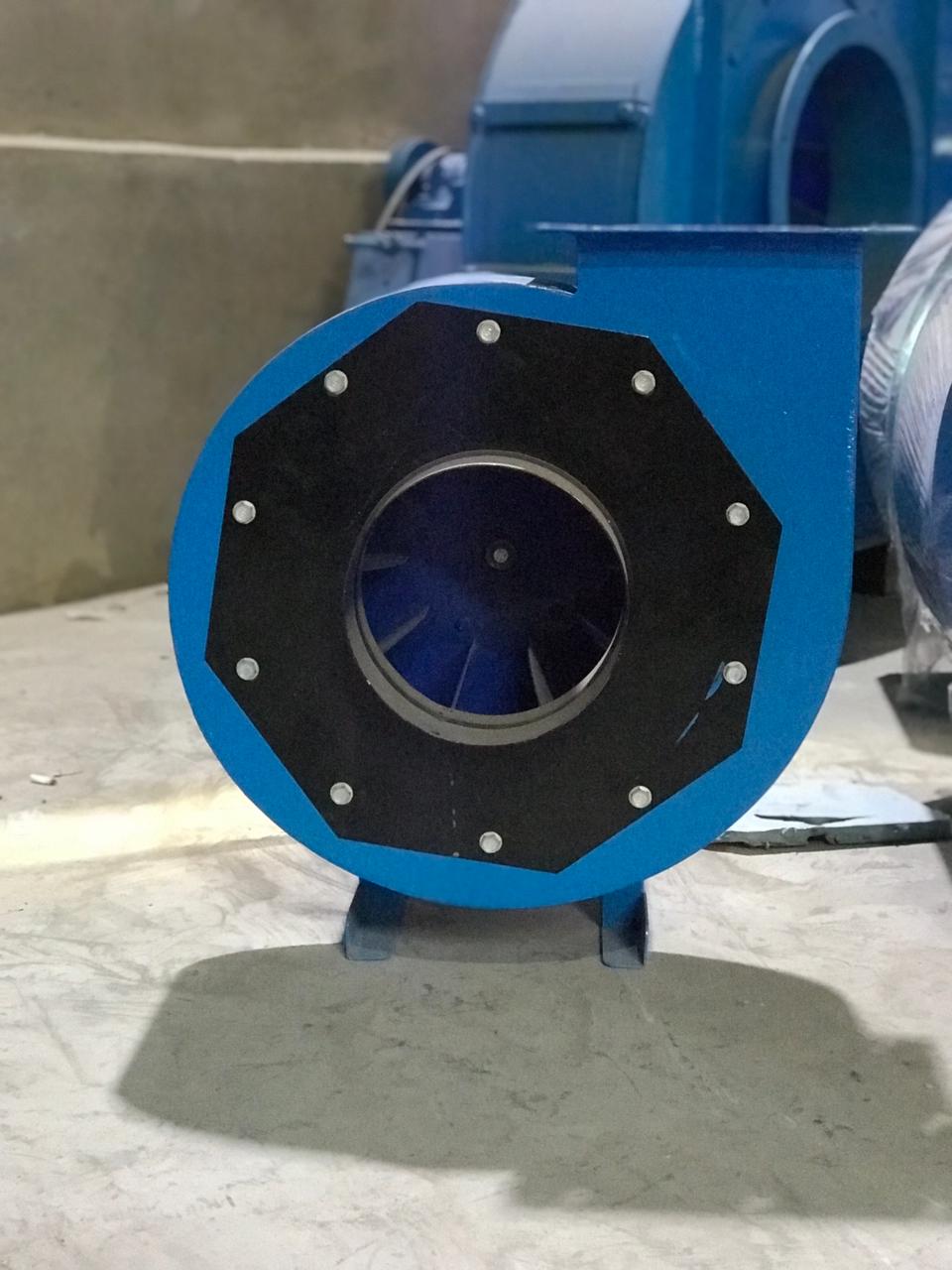

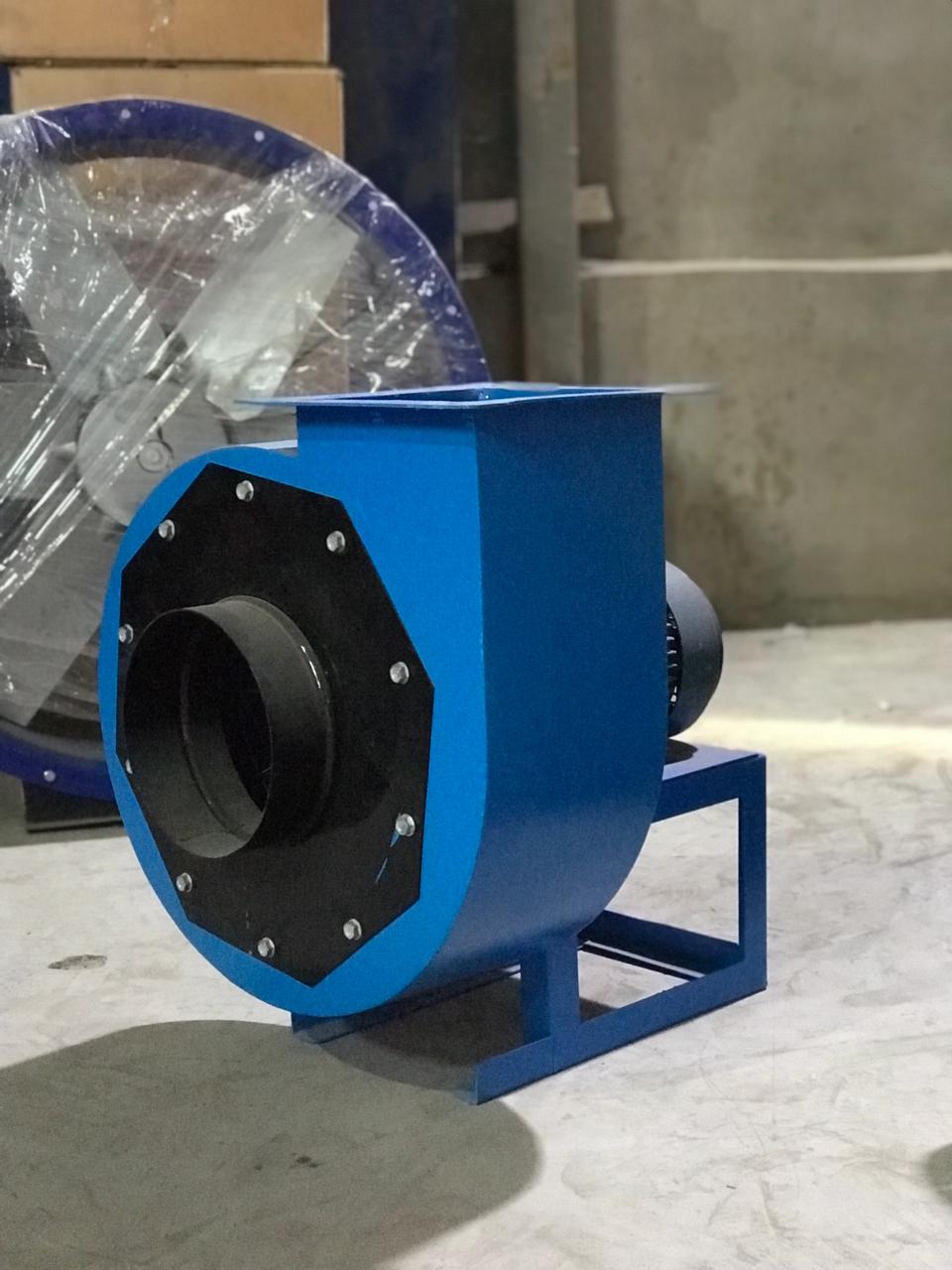

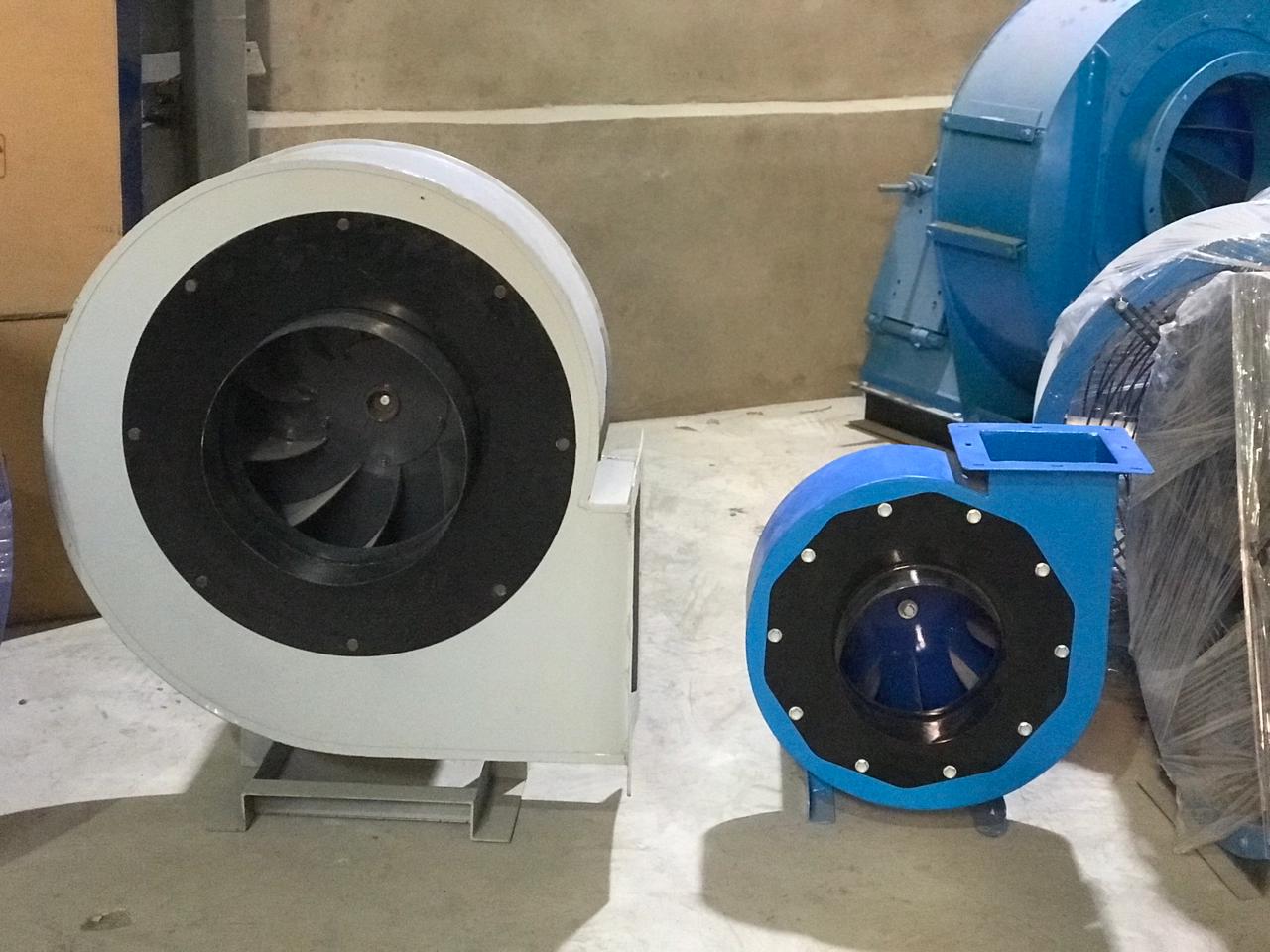

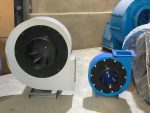

The HKA Industrial Radial Fans – Backward Curved Series are heavy-duty centrifugal fans specifically engineered for industrial ventilation, air movement, and process applications requiring high efficiency, reliability, and durability.

These fans are designed with backward-curved impellers that provide superior aerodynamic performance, high static pressure, and low noise levels. The backward-curved blade profile minimizes dust accumulation and enhances efficiency compared to traditional forward-curved designs.

Constructed from robust welded steel and coated with epoxy or hot-dip galvanized protection, the HKA fans are capable of operating under harsh industrial environments and continuous duty cycles.

The fan assembly consists of a precision-balanced impeller, a heavy-duty base frame, and a TEFC motor mounted either directly on the shaft or via a belt-drive system, depending on performance requirements.

The modular and service-friendly design allows easy access to internal components for inspection and maintenance, ensuring long-term reliability and consistent performance.

Thanks to their rugged structure, energy-efficient airflow characteristics, and versatile configurations, HKA Industrial Radial Fans are widely used in factories, workshops, HVAC systems, dust extraction units, and process ventilation applications.

Reviews

There are no reviews yet.